Glassware production process mainly | Ruixin Glass

2017-02-17 10:46:08

Glassware production process mainly | Ruixin Glass

① raw materials pre-processing. The lime raw materials (quartz sand, soda ash, limestone, feldspar, etc.) crushed, so that the wet raw materials dry, iron-containing raw materials for iron treatment to ensure the quality of glass.

② preparation of ingredients.

③ melt. Glass batch material in the pool kiln or pool furnace for high temperature (1550 ~ 1600 degrees) heating, so that the formation of uniform, no bubbles, and meet the molding requirements of liquid glass.

④ forming. A glass product, such as a flat plate, a variety of utensils, and the like, which are made of liquid glass in a desired shape.

⑤ heat treatment. Through the annealing, quenching and other processes to eliminate or produce the internal stress of the glass, split or crystallization, and change the structure of the glass state.

④ forming. A glass product, such as a flat plate, a variety of utensils, and the like, which are made of liquid glass in a desired shape.

⑤ heat treatment. Through the annealing, quenching and other processes to eliminate or produce the internal stress of the glass, split or crystallization, and change the structure of the glass state.

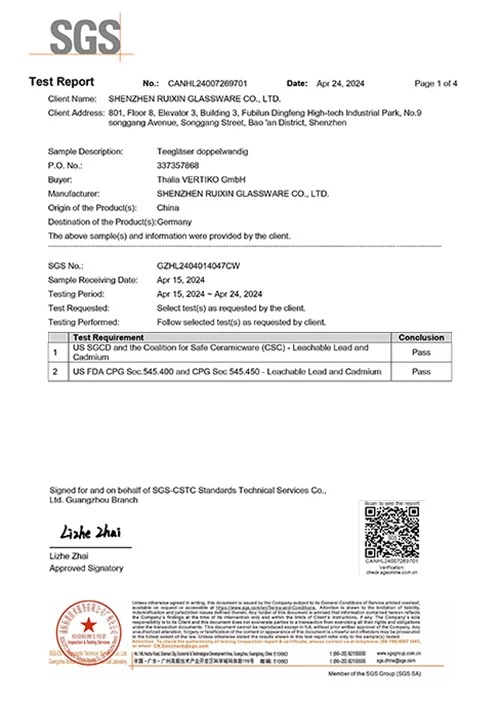

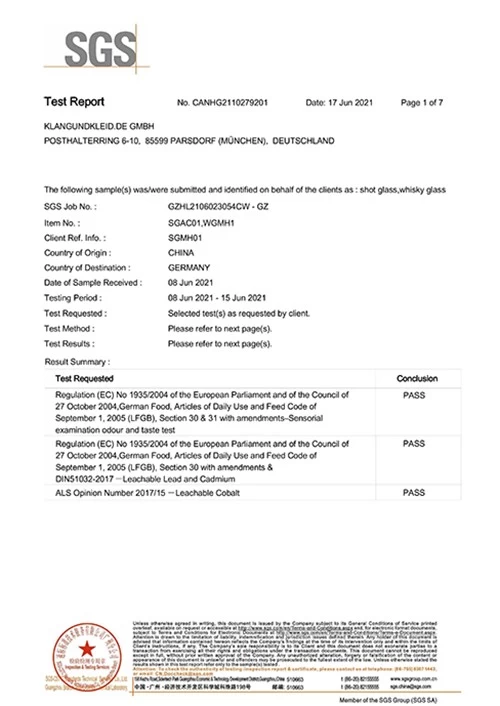

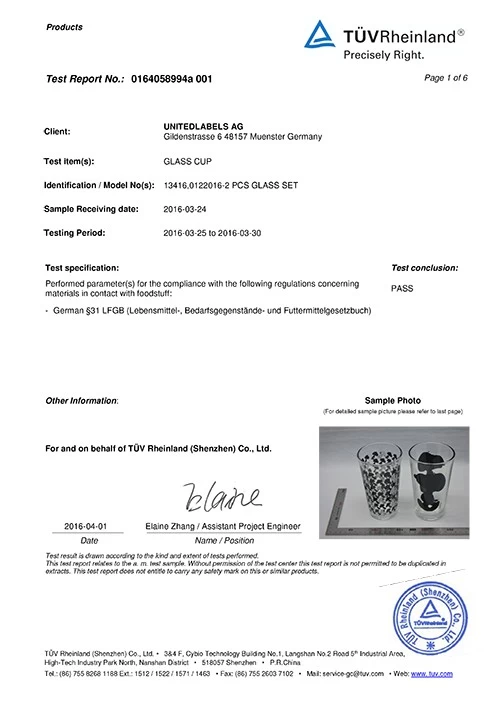

Shenzhen Ruixin Glassware company,10 years experience in customizing glassware gift,Sedex factory audit passed, all product could pass the SGS,FDA,BV and LFGB test.So if you want to do your own colors just contact us.

Shenzhen Ruixin glassware factory is very professional,and have been in this field over 15 years. specialized in the product glassware,glass candle holder,glass perfume bottle,etc.

For more information, you can visit our website: http://www.glassware-suppliers.com or contact info@glassware-suppliers.com directly.