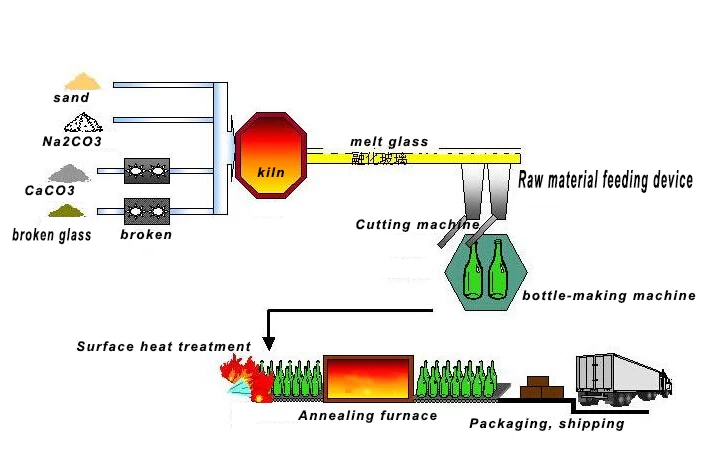

Glass bottles process description

2017-03-20 10:28:21

Glass bottles process description

Main technological flow chart 1, glass bottles are as follows: various raw material → batching → mixing → workshop → weighing feeder glasshouse → → → Forehearth glass furnace melting () → testing, package → → → annealing molding equipment factory

Process process General for: ingredients workshop preparation of is requirements of tie material, by conveying equipment shipped to melt business workshop of kiln head material warehouse, then by feeding machine joined to glass kiln furnace in the, in 1450 ℃ around of high temperature for melting into glass liquid, melting good of glass liquid, again by for material road by for material machine supply forming equipment (business bottle machine,) made by needed of products, again by lost bottle, and push bottle machine, put products into back stove in the for annealing removal stress, by on products of quality for test Hou, qualified of products for packaging storage, and The factory.

(1) ingredient workshop: this workshop built silos, hoisting equipment, weighing equipment, mixing equipment, and so on. Mainly after weighing and mixing of mineral and chemical raw materials, made the required batch. Daily production of the main raw material for glass: limestone, dolomite, feldspar, silica sand, soda ash, and seven or eight kinds of mineral and chemical raw materials such as broken glass.

(2) the glasshouse: the workshop for the glass factory's main production plant, built in glass tank furnace and Forehearth (machine), equipment (bottle), annealing lehrs, inspection and packaging equipment. At present, the plant generally use two layers (part three) arrangement, forming equipment (bottle), annealing lehrs, inspection and packaging equipment on the second floor, inspection of packaging automation.